1. Production Process and Common Quality Issues for Steel

Click to review the detailed production process and common quality issues for steel.

2. Ensuring Steel Safety & Compliance with Laboratory Testing

We arrange laboratory testing to confirm adherence to international safety and performance standards:

- ASTM A370 (Mechanical Testing of Steel Products)

- ISO 6892-1 (Tensile Testing of Metallic Materials)

- ASTM E112 (Determining Average Grain Size)

- RoHS (Restriction of Hazardous Substances)

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

- CE Marking (European Conformity for Construction Products)

- JIS G3101 (General Structural Rolled Steel)

- EN 10025 (Hot Rolled Structural Steel)

3. Common Defects in Steel Inspections

Material & Composition Defects

- Incorrect chemical composition

- Inconsistent hardness or strength

- Presence of non-metallic inclusions

- Segregation of alloying elements

Dimensional & Form Defects

- Incorrect length, width, or thickness

- Out-of-tolerance straightness or flatness

- Uneven edges or camber

- Distortion or warping

Internal Defects

- Blowholes or gas pores

- Laminations or internal cracks

- Incomplete fusion in welded areas

- Inclusions or voids

Surface Defects

- Rust or corrosion

- Scratches, dents, or abrasions

- Scale or oxide layers

- Pitting or surface cracks

4. Which Steel Products Do We Have the Most Experience With?

Structural Steel

- Beams (I-beam, H-beam)

- Channels

- Angles

- Plates

- Rebar

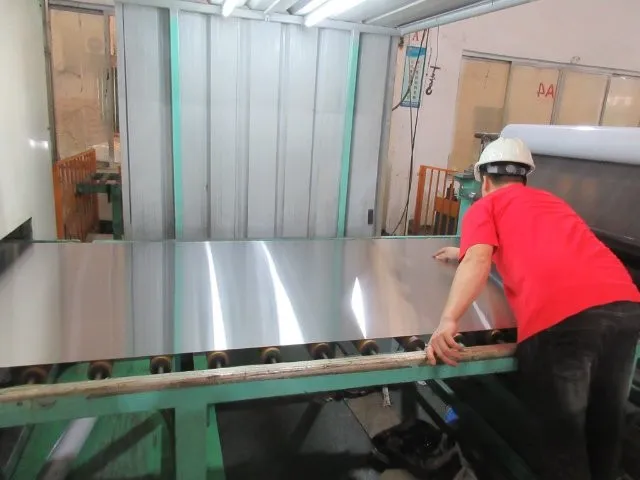

Sheet & Coil Steel

- Hot-rolled Steel sheets

- Cold-rolled Steel sheets

- Galvanized Steel coils

- Stainless Steel sheets

Pipes & Tubes

- Seamless Steel pipes

- Welded Steel pipes

- Square and rectangular tubes

- Precision Steel tubes

Specialty Steel

- Tool Steel

- Alloy Steel

- High-strength low-alloy (HSLA) Steel

- Wear-resistant Steel

5. Our Steel Quality Control Services

Product Inspection

On-site inspections verify steel quality, dimensions, finish, and workmanship.

Supplier Audits

Assess manufacturers’ production capacity, quality systems, and compliance readiness.

Laboratory Testing

Validate mechanical properties, chemical composition, and international standard compliance.

Material Check

Internal Workmanship Check

6. How V-Trust Helps You Find the Right Steel Supplier

We conduct supplier audits to verify production capabilities and compliance before order placement.

Factory Audit

Quick verification of supplier legitimacy through:

- Factory existence and document verification

- Basic production capacity review

- Contact person verification

In-Depth Factory Audit

A comprehensive evaluation covering:

- Production capacity & facility assessment

- Quality control system evaluation

- Social compliance verification

7. How V-Trust Helps You Control the Quality of Steel

V-Trust offers a comprehensive quality control solution that covers all stages from initial sample verification to final container loading, including Sample Checks, Production Monitoring, During Production Inspection, Pre-Shipment Inspection, and Container Loading Supervision, ensuring your steel products meet stringent quality and safety standards. Our expert team is dedicated to minimizing risks and ensuring compliance throughout your supply chain.

Sample Check

Before mass production, V-Trust engineers meticulously evaluate steel samples for critical attributes such as chemical composition, mechanical properties (tensile strength, yield strength, elongation), surface finish, and dimensional accuracy. This ensures the sample aligns with your specifications and industry standards, preventing costly issues down the line.

Production Monitoring

During Steel production, our on-site inspectors continuously monitor key processes like rolling, heat treatment, and cutting. They track parameters such as temperature, rolling speed, and cooling rates to identify and address potential issues like surface defects, dimensional inconsistencies, or material segregation in real-time, ensuring consistent quality throughout the production run.

During Production Inspection

When at least 10% of the Steel order is completed, V-Trust conducts a detailed inspection to detect early-stage problems. This includes checking for surface flaws, dimensional deviations, and initial mechanical property tests. Identifying these issues early allows for timely corrective actions, reducing rework and preventing delays in delivery.

Pre-Shipment Inspection

Once 80-100% of the Steel order is finished and packed, a comprehensive Pre-Shipment Inspection is performed. This final check verifies the overall product quality, quantity, packaging integrity, and labeling accuracy. We confirm that the Steel meets all specified requirements, including material grade, dimensions, surface condition, and proper bundling/marking for shipment.

Container Loading Supervision

V-Trust supervises the entire container loading process for Steel products. Our inspectors ensure that the correct quantity and type of Steel are loaded, that proper securing methods (e.g., bracing, dunnage) are used to prevent shifting and damage during transit, and that the container itself is clean and suitable for transport.

8. The Most Related Sourcing Fairs in Asia

Tube China

Shanghai New International Expo Centre (SNIEC), Shanghai, ChinaTube China showcases the latest innovations, technologies, and trends in tube manufacturing and processing, including raw materials, tube manufacturing machinery, heat treatment, cutting, and testing equipment.

https://www.tubechina.net/en/

Metal + Metallurgy China (China International Foundry Expo)

National Exhibition and Convention Center (NECC), Shanghai, ChinaThis event covers the entire ferrous and nonferrous industrial chain, featuring high-quality castings, casting equipment, raw and auxiliary materials, quality inspection equipment, molds, and automation solutions.

https://www.expochina.cn/en/index

China (Guangzhou) International Metal & Metallurgy Exhibition

China Import and Export Fair Pazhou Complex, Guangzhou, ChinaThis fair in Asia focuses on the metal and metallurgical industries, including plate metal, bar, wire, Steel rope, metal processing and setting equipment, stainless Steel, and casting.

https://www.julang.com.cn/english/

Why Choose V-Trust for Steel Quality Control?

Asia's leading product inspection company with full-time, professionally trained inspectors and comprehensive accreditation for inspection, audit, and lab testing services.

Steel Quality Control: Frequently Asked Questions (FAQ)

Why do I need product inspections for steel?

If you are worried about or have experienced problems such as poor quality, incorrect shipments, or wrong packaging for goods imported from Asia, product inspection services is your solution. V-Trust product inspection service can help you have accurate understanding about the quality of the steel without going to the factory by yourself.

Do I need to send you an approved sample of steel?

It would be great if you can send the approved sample to V-Trust before the inspection for reference. Compared with product photos or specification documents, a real product sample allows V-Trust engineers to do a more thorough comparison check.

How many days in advance should I book the pre-shipment inspection?

Though sometimes it's possible to book next-day inspections for many manufacturing clusters where V-Trust has a large team of full-time inspectors, we recommend booking with us at least three days in advance. Early booking is important for appropriate scheduling and good preparation before the inspection.

Who will I be in contact with throughout the whole process?

There will be one dedicated account manager who will be assigned as your main contact point at V-Trust. You will receive prompt responses whenever you have any questions regarding the inspection arrangement.

How long does it take to know the inspection result?

The official report, reviewed and signed by an authorized V-Trust technical manager, will be available within 24 hours after each inspection. Same day report is available if you would like to know about the inspection findings on the same day. V-Trust has the highest same day report rate in the inspection industry.

What if I have questions after I check my V-Trust report?

Please don’t hesitate to contact us whenever you have any questions. V-Trust team is always available even after the inspection is completed.

Request Your Inspection Today

Ready to ensure the quality of your products? Contact our team to discuss your specific requirements.