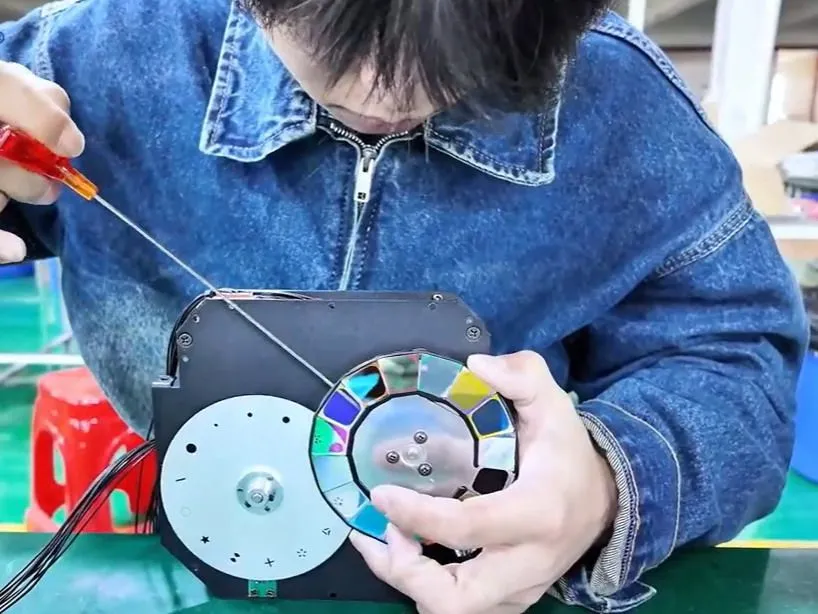

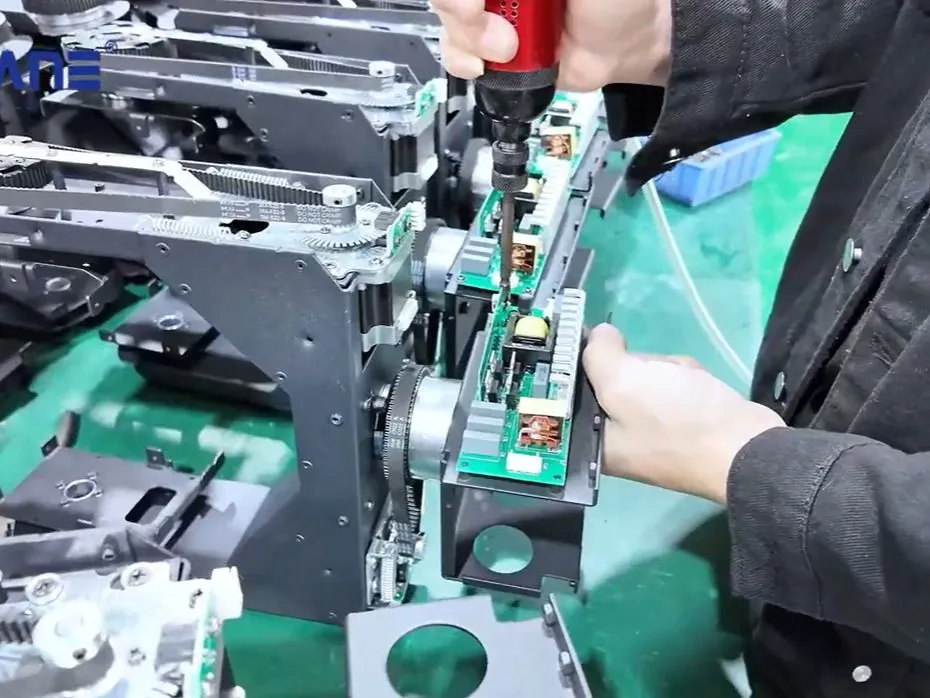

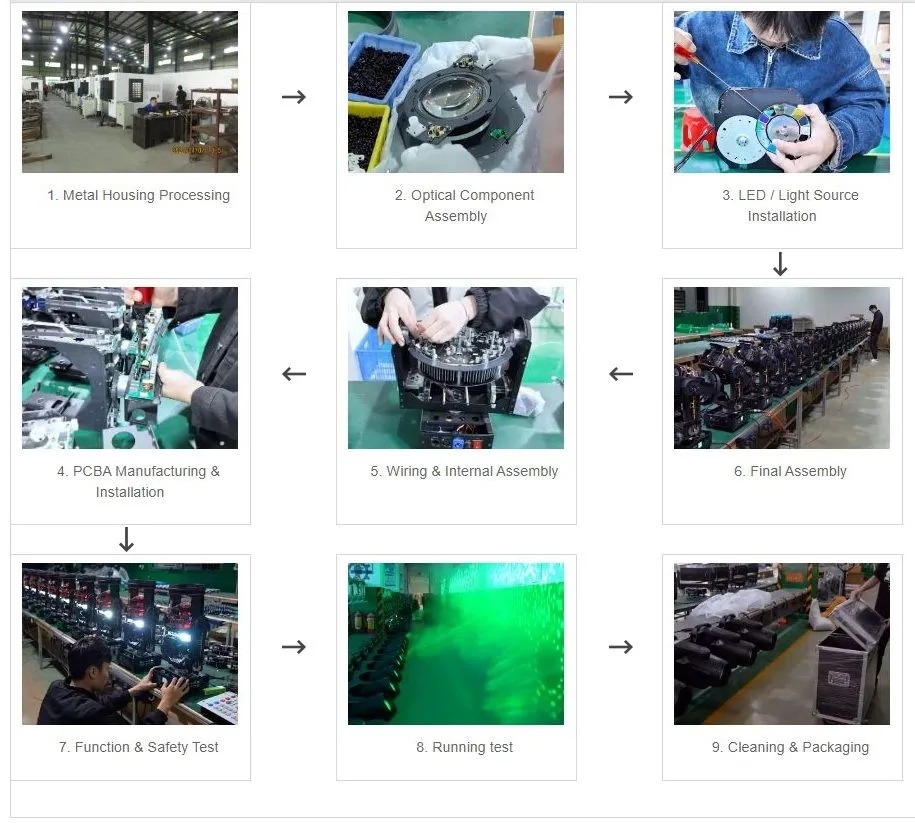

1. Production Process and Common Quality Issues for Stage Lighting Products

Click to review the detailed production process and common quality issues for stage lighting products.

2. Ensuring Stage Lighting Safety & Compliance with Laboratory Testing

To access global markets, stage lighting products must meet strict regulatory and testing standards. V-Trust provides independent sample selection directly from production lines and arranges laboratory testing to ensure full compliance.

We conduct testing for the following standards:

- CE & RoHS Compliance (Environmental & safety testing)

- IEC 60598-1 (Luminaires safety requirements)

- EMC Testing (Electromagnetic compatibility)

- IP Rating Tests (Waterproof & dustproof performance)

- Luminous Flux & Color Temperature Tests

- FCC Part 15 for electromagnetic interference (EMI)

3. Common Defects in Stage Light Product Inspections

Appearance

- Scratches, cracks, or dents

- Misaligned components

- Incorrect finishing or coating defects

- Uneven color or inconsistent paint

Specification

- Incorrect brightness or wattage

- Wrong LED chip type or quantity

- Improper beam angle

- Inconsistent color temperature (e.g., mixed warm/cool white)

Safety

- Loose wiring or poor soldering

- Exposed electrical components

- Non-compliant safety certification labels

- Overheating issues (poor heat dissipation)

Packing

- Damaged cartons

- Missing accessories (mounting brackets, remote controllers, etc.)

- Incorrect user manuals

- Inadequate protective packaging (e.g., no foam or bubble wrap)

4. Which Stage Lighting Products Do We Have the Most Experience with?

Effect & Performance Lighting

- Moving Head Lights

- LED Par Lights

- Follow Spot Lights

- Laser Lights

Support & Control Equipment

- Fog Machines & Hazers

- Stage Controllers & Dimmers

- Trusses & Rigging Equipment

- Stage Strobe Lights

5. Our Stage Lighting Products Quality Control Services

Product Inspection

We inspect stage lights on-site to verify quality, function, and workmanship against your exact specifications.

Supplier Audits

We audit manufacturers before your order to confirm their capability, process control, and quality system readiness.

Laboratory Testing

We test stage lights in our labs for electrical safety, thermal performance, IP rating, and regional compliance (e.g., CE, UL, PSE).

DMX Console Control Function Test

Wireless Control Function Test

6. How V-Trust Helps You Find the Right Stage Lighting Products Supplier

V-Trust dispatches qualified auditors to perform tailored audits, ensuring your supplier meets your specific needs. Conducted before placing deposits, our audits help mitigate risks.

Factory Audit

Quickly verify supplier legitimacy with checks on:

- Factory existence and document verification (certificates, business licenses, etc.)

- Basic production capacity review

- Contact person verification

In-Depth Factory Audit

A deeper dive into supplier capabilities, including:

- Production capacity and facilities assessment

- Quality control system evaluation

7. How V-Trust Helps You Control the Quality of Stage Lighting Products

V-Trust ensures consistent product quality and compliance throughout the production process with a full range of services, including Sample Checks, During Production Inspection, Pre-Shipment Inspection, Production Monitoring, and Container Loading Supervision.

Sample Check

Our engineers evaluate product samples for quality, safety, functionality, and specifications in V-Trust's lab, helping you compare different suppliers and make informed decisions.

Production Monitoring

Ongoing oversight ensures quality standards are met, with corrective actions to improve the factory's quality management system.

During Production Inspection

We conduct inspections when at least 10% of production is completed to detect defects early, minimize errors, and keep production on schedule.

Pre-Shipment Inspection

At the end of production, we conduct a final check to verify:

- Product quality and compliance

- Functionality, safety, performance, and internal construction

- Product specifications

- Secure and regulatory-compliant packaging

- Accurate quantities

- Marking & labeling

Container Loading Supervision

We verify packaging, labeling, and quantities before dispatch, ensuring proper loading, handling, and container conditions to prevent damage during transportation.

8. The Most Related Sourcing Fairs in Asia

Prolight + Sound Guangzhou

China Import and Export Fair Complex, Guangzhou, ChinaThis fair showcases a wide range of products, including stage lighting, LED displays, sound equipment, and broadcasting solutions.

https://prolight-sound-guangzhou.hk.messefrankfurt.com/guangzhou/en.html

PALM Expo India

Bombay Exhibition Centre (BEC), Mumbai, IndiaALM Expo India gathers cutting-edge global audiovisual technologies and showcases a wide range of leading products in the professional audio, lighting, and audiovisual fields.

https://www.palmexpo.in/

GETshow Guangzhou

Guangzhou Pazhou Poly World Trade Center Expo, Guangzhou, ChinaGETshow Guangzhou is featuring core segments such as professional audio equipment, lighting systems, audiovisual technology, and stage machinery devices.

https://www.getshow.com.cn/en

Why Choose V-Trust for Stage Lighting Products Quality Control?

Asia's leading product inspection company with full-time, professionally trained inspectors and comprehensive accreditation for inspection, audit, and lab testing services.

Stage Lighting Products Quality Control: Frequently Asked Questions (FAQ)

Why do I need a shipment inspection for stage lights?

If you have experienced issues or want to take precautions on the functionality, appearance, packaging, or overall quality of your stage lighting products, product inspection services are essential. V-Trust's inspection services help you gain an accurate understanding of the quality of your goods without needing to visit the factory personally.

Will you test the lighting performance during the inspection?

Yes, we conduct functional and brightness tests, along with beam angle and color temperature checks, to ensure your lights perform as expected.

How many days in advance should I book the inspection?

We recommend booking at least three days in advance, although in some manufacturing areas with a large team of inspectors, next-day inspections may be possible.

Do I need to send you an approved sample?

Approved samples are highly recommended for the inspection process, as they help our engineers understand the product specifications and focus on critical areas during the inspection.

How long does it take to get my report?

The official inspection report will be reviewed and signed by a technical manager and made available within 24 hours after the inspection. A draft report is also available on the same day after the inspection.

What if I have questions after receiving the report?

Our services don’t end after the report is issued. Our team is available to clarify any aspects of the inspection report as needed.

Request Your Inspection Today

Ready to ensure the quality of your products? Contact our team to discuss your specific requirements.