Solar Panel Quality Control Services in Asia

including China, Vietnam, India, Cambodia, Bangladesh, Thailand, Malaysia, Indonesia, Myanmar and Pakistan

V-Trust provides comprehensive quality control services for solar panel products to ensure compliance with your specifications and international standards. Operating across 10 Asian countries with 600+ well-trained full-time employees, V-Trust delivers reliable product inspections, supplier evaluations, and lab testing services, guaranteeing that your solar panels meet quality, performance, and safety requirements.

How V-Trust Helps You Find the Right Solar Panel Supplier

We conduct supplier audits to verify production capabilities and compliance before order placement.

Simple Factory Audit

Quick verification of supplier legitimacy, including:

- Factory existence and document verification (certificates, business licenses, etc.)

- Basic production capacity review

- Contact person verification

Factory Audit

A comprehensive assessment of supplier reliability, covering:

- Production capacity & facility assessment

- Quality control system evaluation

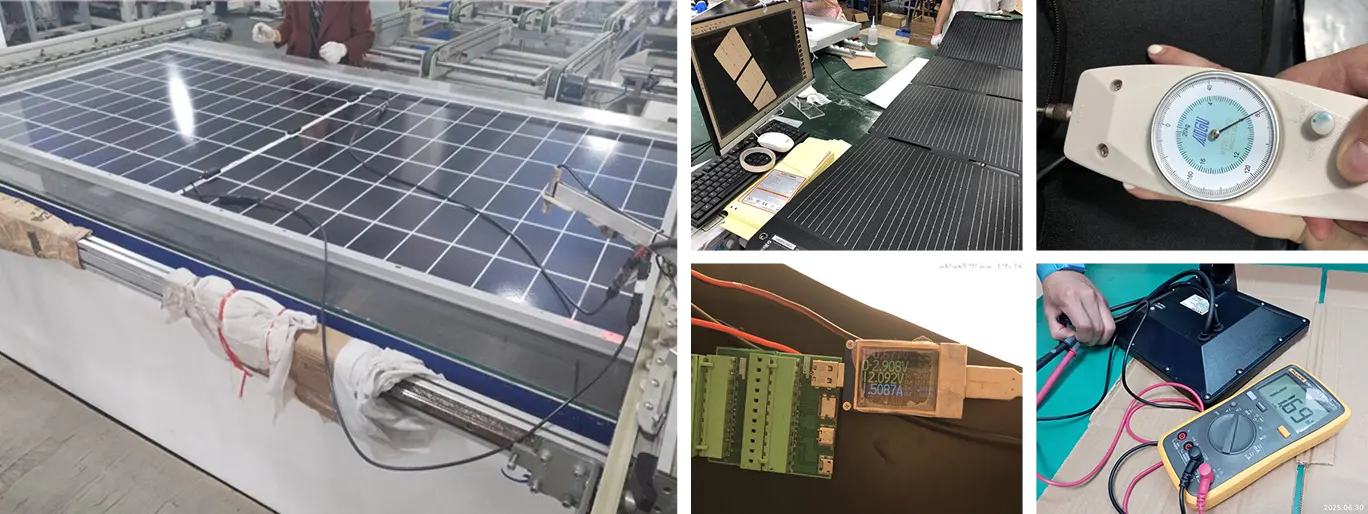

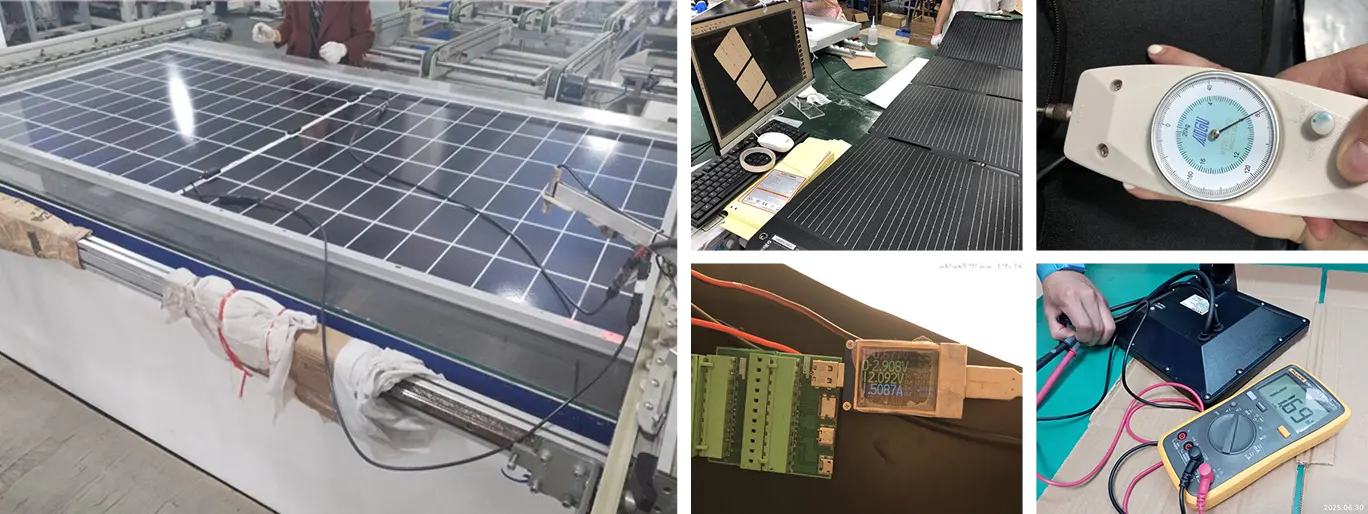

How V-Trust Helps You Control the Quality of Solar Panels

V-Trust delivers comprehensive solar panel inspection services, ensuring consistent product quality and regulatory compliance. Our quality control solutions cover all stages of smartphone production, including Sample Checks, Production Monitoring, During Production Inspection, Pre-Shipment Inspection, and Container Loading Supervision, reducing the risk of product failures and costly recalls.

Sample Check

Our engineers evaluate solar panel samples for structural integrity, electrical performance, and safety compliance. We conduct lab tests on power output consistency, potential-induced degradation (PID) resistance, junction box sealing, and frame durability, ensuring your supplier meets the technical specifications before mass production begins.

Production Monitoring

We provide on-site oversight during solar panel manufacturing to track cell sorting accuracy, lamination process stability, and frame alignment precision. Our inspectors identify early risks such as micro-crack formation during tabbing, bubble generation in EVA encapsulation, or bypass diode miscalibration, enabling real-time corrections to maintain quality standards.

During Production Inspection

Once at least 10% of the order is completed, we perform mid-production inspections to evaluate:

- Cell defect density (via electroluminescence imaging)

- Insulation resistance

- Wet leakage current compliance

- Labeling accuracy for wattage and certifications

This intercepts systemic flaws before full-batch completion.

Pre-Shipment Inspection

Before shipping, we conduct comprehensive final checks to confirm:

- Actual power output within tolerance (flash tester)

- Glass surface integrity (e.g., scratches/chips ≤2mm)

- Frame corrosion resistance and geometric tolerance

- Compliant packaging with moisture barriers

- Complete documentation including IEC/UL marks

Container Loading Supervision

We verify stacking configuration (max. 8 layers for glass-glass panels), moisture barrier deployment, and container floor conditions. Our team ensures secure strapping, proper pallet positioning, and prevents transit damage from shifting or humidity exposure.