Solar Cell Quality Control Services in Asia

including China, Vietnam, India, Cambodia, Bangladesh, Thailand, Malaysia, Indonesia, Myanmar and Pakistan

V-Trust provides comprehensive quality control services for solar cell products to ensure compliance with your specifications and international standards. Operating across 10 Asian countries with 600+ well-trained full-time employees, V-Trust delivers reliable product inspections, supplier evaluations, and lab testing services, guaranteeing that your solar cell meet quality, performance, and safety requirements.

How V-Trust Helps You Find the Right Solar Cell Supplier

We conduct supplier audits to verify production capabilities and compliance before order placement.

Simple Factory Audit

Quick verification of supplier legitimacy, including:

- Factory existence and document verification (certificates, business licenses, etc.)

- Basic production capacity review

- Contact person verification

Factory Audit

A comprehensive assessment of supplier reliability, covering:

- Production capacity & facility assessment

- Quality control system evaluation

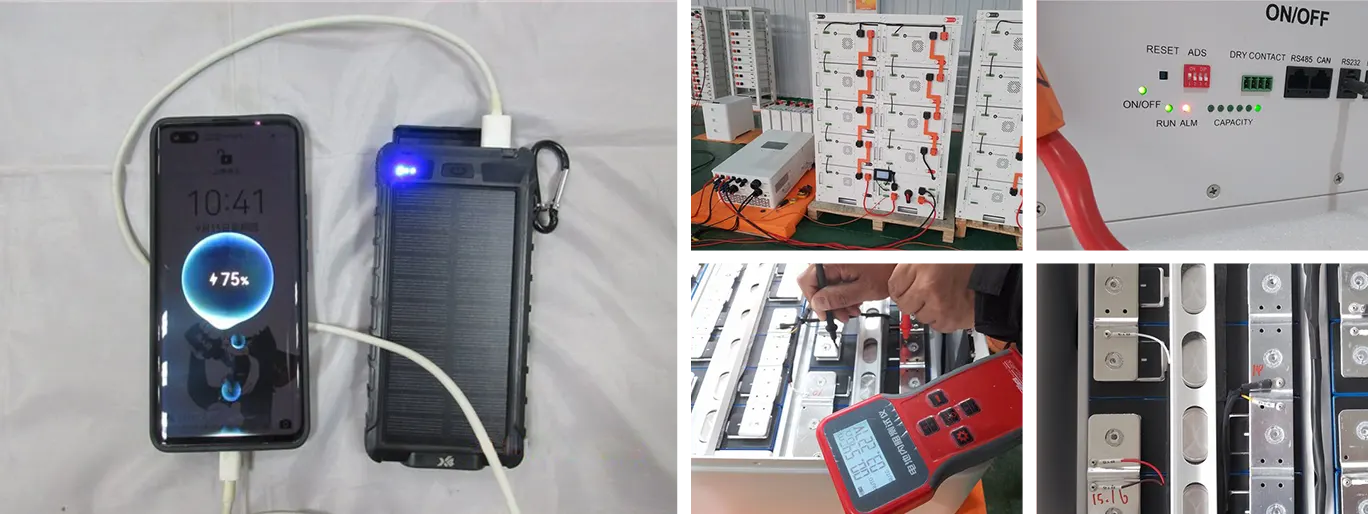

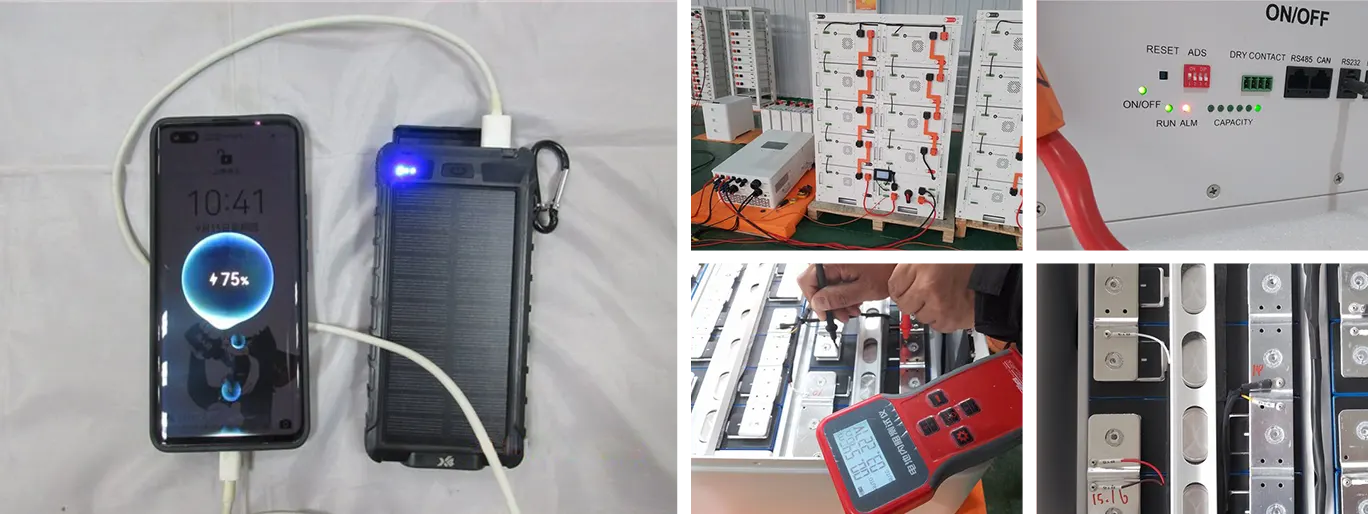

How V-Trust Controls Solar Cell Quality

V-Trust delivers comprehensive solar cell inspection services, ensuring consistent product quality and regulatory compliance. Our quality control solutions cover all stages of smartphone production, including Sample Checks, Production Monitoring, During Production Inspection, Pre-Shipment Inspection, and Container Loading Supervision, reducing the risk of product failures and costly recalls.

Sample Check

Our engineers evaluate solar cell samples for conversion efficiency, material integrity, and safety compliance in certified labs. We verify cell grading, junction box waterproofing, and EL (electroluminescence) imaging results, ensuring performance aligns with technical specifications before mass production.

Production Monitoring

We conduct on-site oversight during critical stages like cell stringing, lamination, and framing. Our team tracks soldering quality, EVA film adhesion, and glass alignment to prevent delamination or micro-cracks before mass production advances.

During Production Inspection

Once at least 10% of the smartphone order is completed, we inspect randomized units for:

- Cell layup accuracy and tabbing integrity

- PID (Potential Induced Degradation) susceptibility

- Frame corner strength and grounding continuity

- Preliminary IV curve performance

This intercepts critical defects before full production completion.

Pre-Shipment Inspection

Before shipping, we perform full validation to confirm:

- Glass impact resistance and anti-reflective coating

- Junction box waterproofing and cable gauge

- Packaging durability

- Certification labels and documentation

Container Loading Supervision

We verify pallet stacking, moisture barrier installation, and battery component segregation. Container floor conditions and secure lashing are monitored to prevent glass breakage or corrosion during transit.