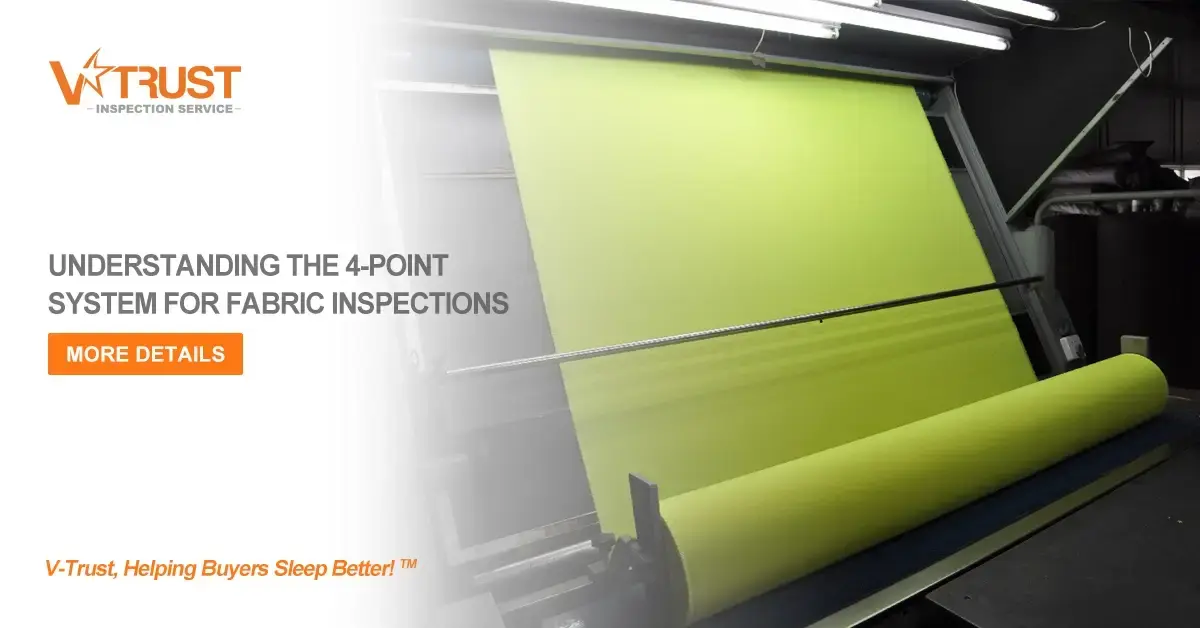

Fabric Quality Control Services in Asia

including China, Vietnam, India, Cambodia, Bangladesh, Thailand, Malaysia, Indonesia, Myanmar and Pakistan

Looking to source fabrics from Asia?

V-Trust helps ensure that every shipment of fabrics meets your specifications and international quality standards. With operations in 10 Asian countries and 600+ well-trained full-time employees, we provide comprehensive product inspections, factory audits, and lab testing services tailored for the textile and apparel industry.

From raw materials to final packaging, we help you maintain consistency, avoid costly quality issues, and work with trustworthy suppliers.

How V-Trust Helps You Select the Right Fabric Supplier

V-Trust dispatches qualified auditors to perform tailored audits, ensuring your fabric supplier meets your sourcing and quality requirements. These audits are typically conducted before placing deposits, helping you minimize sourcing risks.

Simple Factory Audit

Quick verification of supplier legitimacy through:

- Factory existence and registration document checks (e.g. licenses, certificates)

- Basic production capacity review

- Contact person verification

Factory Audit

In-depth assessment of supplier capabilities, including:

- Fabric production equipment and capacity evaluation (weaving, dyeing, finishing)

- Internal quality control system and process management review

How V-Trust Helps You Control the Quality of Fabrics

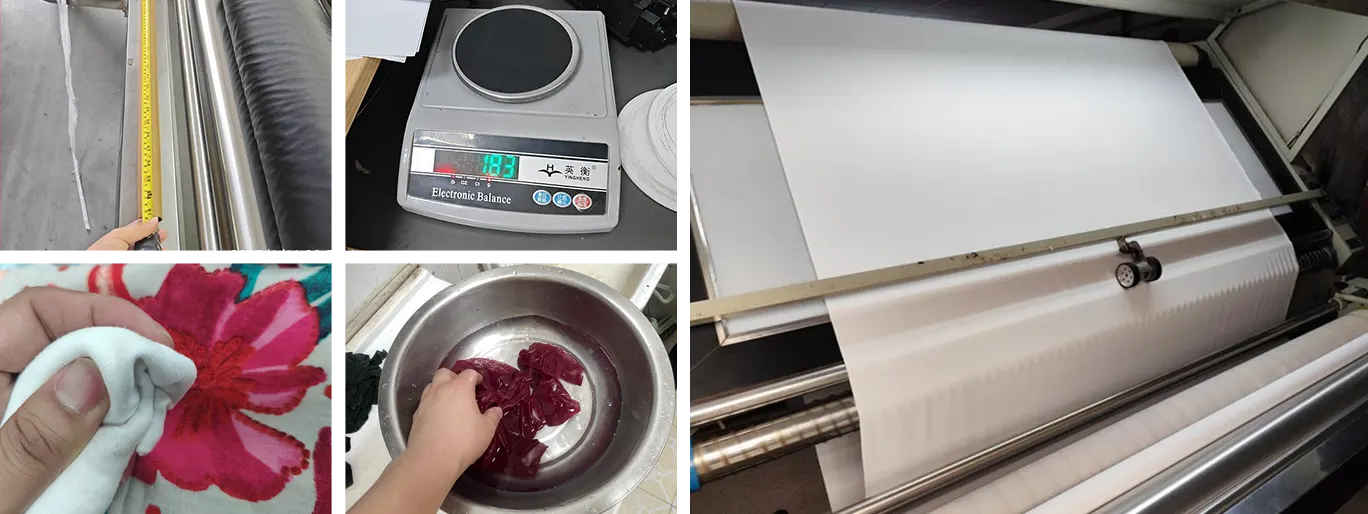

V-Trust ensures consistent fabric product quality and regulatory compliance throughout the entire production process. Our full range of garment inspection services, including Sample Checks, Production Monitoring, During Production Inspection, Pre-Shipment Inspection, and Container Loading Supervision, helps you minimize defects, enhance performance, and meet safety standards for fabric.

Sample Check

We assess fabric samples to review weaving quality, GSM, dyeing uniformity, shrinkage, and colorfastness—helping you select reliable suppliers before mass production.

Production Monitoring

Our inspectors stay on-site to monitor fabric production in real time, identifying issues like weaving defects, color inconsistencies, or incorrect GSM early—supporting factories to maintain stable production and minimize quality fluctuations.

During Production Inspection

Conducted when at least 10% of fabric rolls are finished, this inspection detects early-stage problems such as weaving flaws, inconsistent width, or mislabeling—giving you time to correct issues before completion.

Pre-Shipment Inspection

A final quality check before shipment to verify:

- Overall fabric quality, workmanship, and conformity to standards

- GSM, color consistency, and shrinkage control

- Labeling accuracy and packaging condition

- Cleanliness and correct quantity of fabric rolls

Container Loading Supervision

We ensure your fabrics are properly packed, correctly labeled, and loaded into clean, dry containers—preventing damage from moisture, contamination, or incorrect handling during transport.