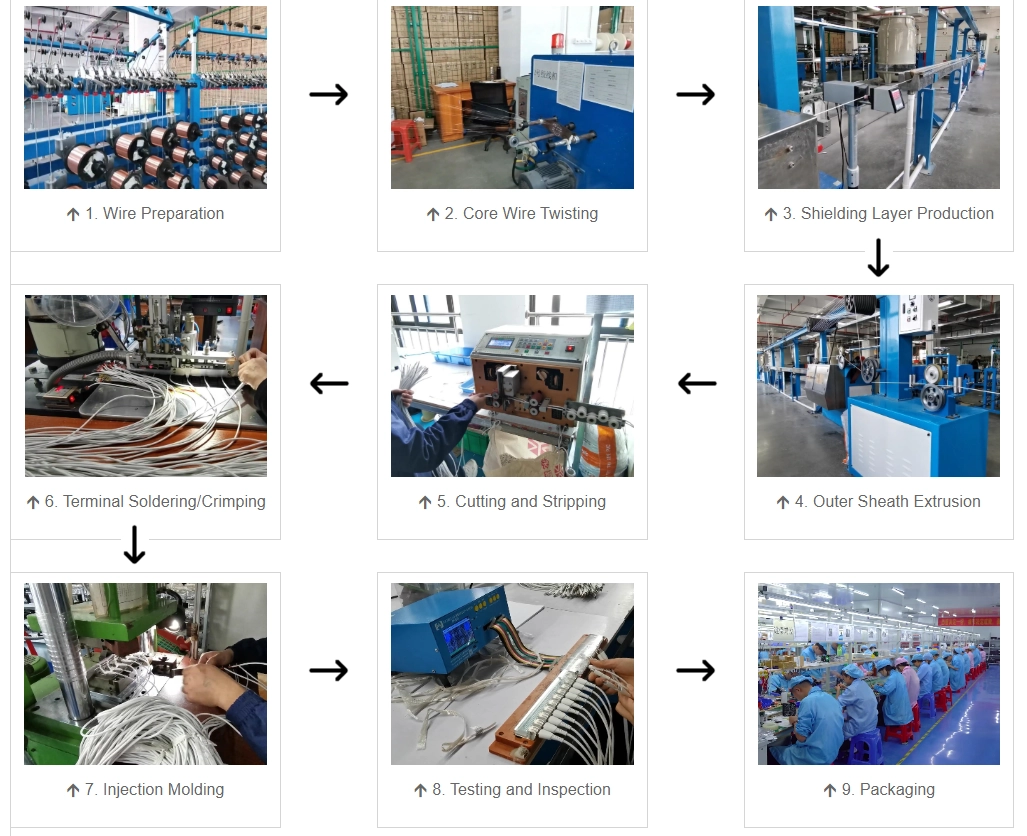

Process 1. Wire Preparation

Key processes: Copper wire drawing, stranding, and insulation extrusion. Draw high-purity copper rods into thin copper wires, strand multiple copper wires into conductors, and then extrude the insulation layer.

Main equipment: Wire drawing machine, stranding machine, and extruder.

Major problem: Copper wire breakage/burrs.

Process 2. Core Wire Twisting

Key processes: Twist multiple insulated core wires according to specific requirements (such as pair twisting, star twisting) to reduce signal interference.

Main equipment: Pair twisting machine and cabling machine.

Major problem: Uneven lay length, loose twisting.

Process 3. Shielding Layer Production

Key processes: Wrap aluminum foil or braided copper mesh around the stranded core wires to form a shielding layer and prevent electromagnetic interference.

Main equipment: Wrapping machine and braiding machine.

Major problem: Incomplete shielding coverage.

Process 4. Outer Sheath Extrusion

Key processes: Extrude outer sheaths made of materials such as PVC and TPE around the shielding layer to provide protection and insulation.

Main equipment: Extruder.

Major problem: Uneven/eccentric outer sheath thickness.

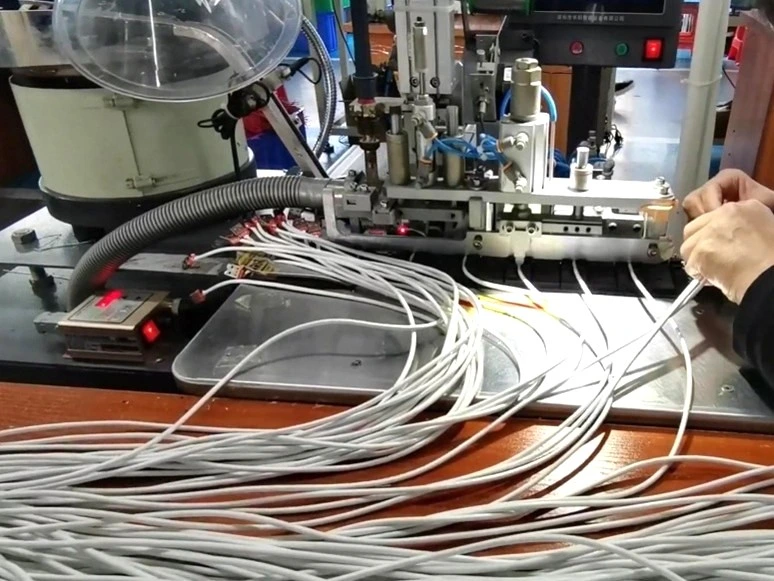

Process 5. Cutting and Stripping

Key processes: Cut the entire roll of data cables into the required length, and strip off the outer sheath and insulation layer at both ends to expose the conductors.

Main equipment: Automatic wire cutting and stripping machine.

Major problem: Inaccurate cutting length.

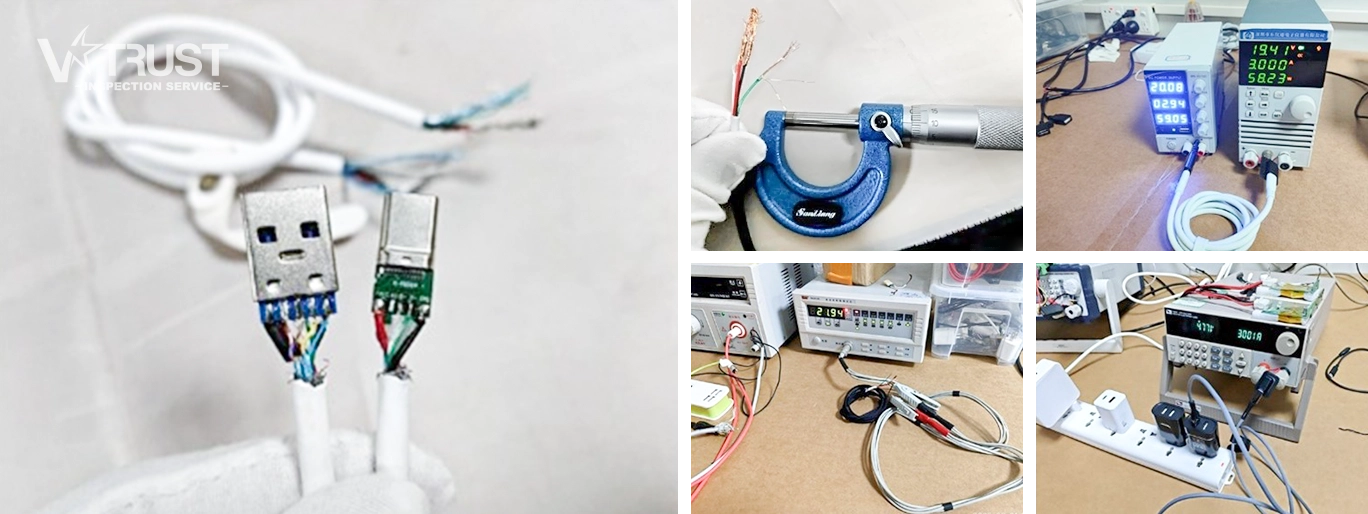

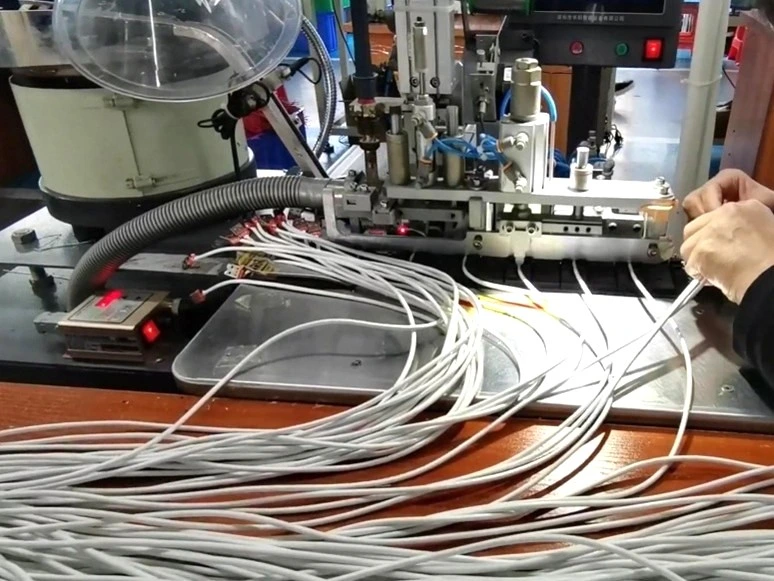

Process 6. Terminal Soldering/Crimping

Key processes: Fix connector terminals (such as USB-A, USB-C, Lightning) to the stripped core wires by means of soldering or crimping.

Main equipment: Automatic soldering machine and terminal crimping machine.

Major problem: Cold solder joints/dry joints, short circuits, reverse polarity.

Process 7. Inner/Outer Molding Injection

Key processes: Perform the first injection molding outside the soldered/crimped terminals to form an inner mold, which fixes the terminals and provides insulation protection; perform the second injection molding outside the inner mold to form the shell of the data cable connector, which provides appearance and further protection.

Main equipment: Injection molding machine.

Major problem: Incomplete molding/short shot, flash/burrs.

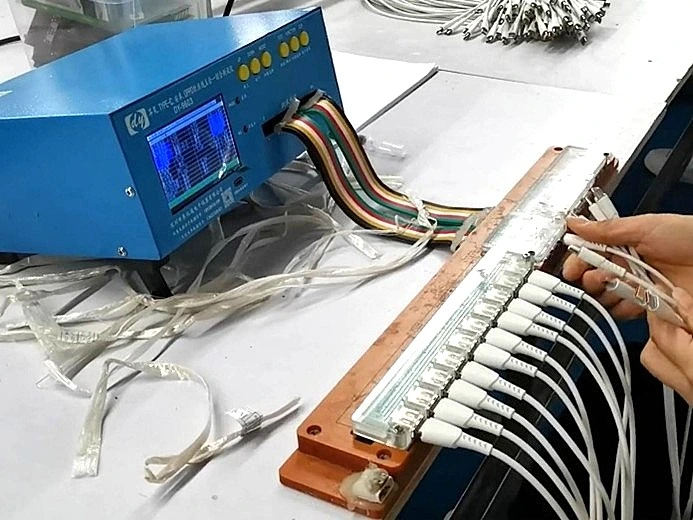

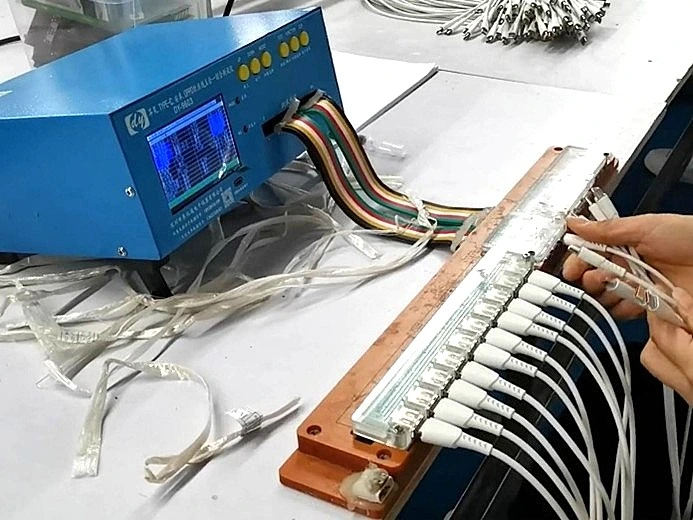

Process 8. Testing and Inspection

Key processes: Conduct various performance tests such as continuity, insulation, withstand voltage, flexing, and insertion/extraction force on the finished data cables to ensure product quality.

Main equipment: Comprehensive tester, flexing tester, and insertion/extraction force tester.

Major problem: Test equipment malfunction/inaccurate calibration, missed inspection.

Process 9. Packaging

Key processes: Clean, bundle, label, and box the products to complete the final product packaging.

Main equipment: Packaging machine and sealing machine.

Major problem: Packaging damage, incorrect/missing labels, missing accessories.