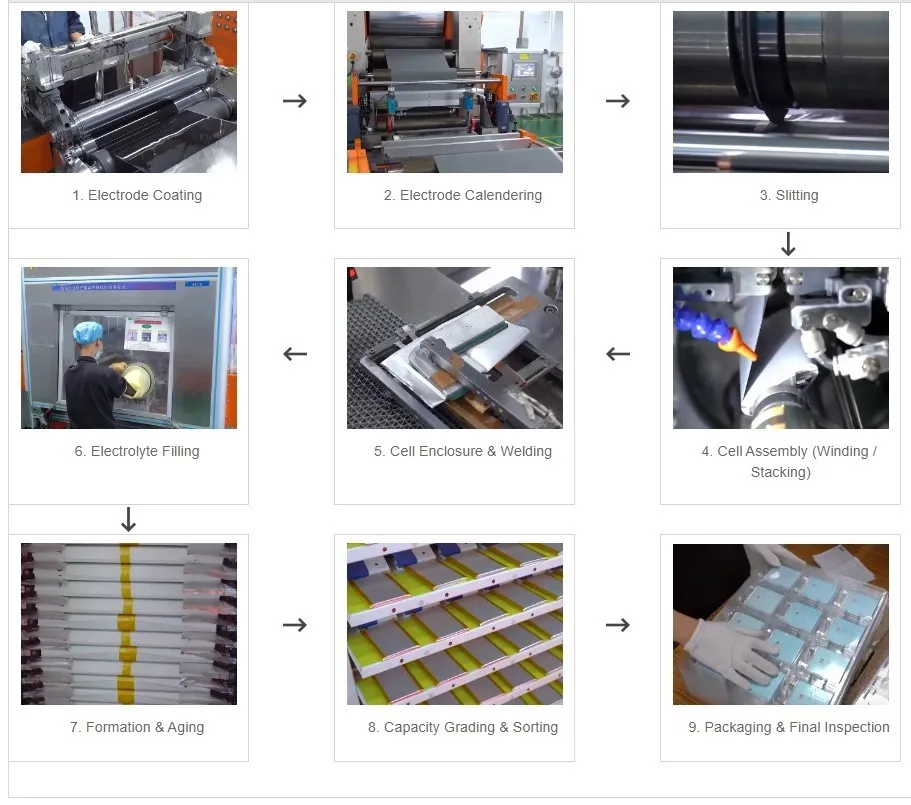

1. Production Process and Common Quality Issues for Li-ion Battery Products

Click to review the detailed production process and common quality issues for Li-ion battery products.

2. Ensuring Battery Safety & Compliance with Lab Testing

We arrange laboratory testing to confirm adherence to international safety and performance standards:

- Environmental: RoHS, REACH, CA65

- Abuse Testing: Short circuit, overcharge, nail penetration

- Transportation: UN 38.3

- Performance: IEC 61960 (capacity/cycle life)

3. Common Defects in Li-ion Battery Product Inspections

Safety Risks

- Swelling/leaking cells

- High resistance

- Poor insulation (risk of short circuit)

- Wrong Battery positive and negative poles marking

Performance Issues

- Capacity deviation (>±5%)

- High self-discharge rate

- Voltage inconsistency across packs

- Cycle Life Below Standard

Construction Defects

- Spot-weld failures (anode/cathode)

- Damaged separators

- Poor sealing (moisture ingress)

- Loose terminal connections

Certification Gaps

- Blurry or Missing Labels/Markings (UL, IEC, UN38.3)

- Non-compliant labeling (mAh, voltage, warnings)

- Incorrect MSDS documentation

4. Which Li-ion Battery Products Do We Have the Most Experience With?

Portable Batteries

- Power banks, consumer electronics

EV Batteries

- Packs & modules for e-scooters/e-bikes

- Energy Storage Systems (ESS): Home & grid solutions

- Industrial Batteries: Medical devices, robotics, UP

5. Our Li-ion Battery Product Quality Control Services

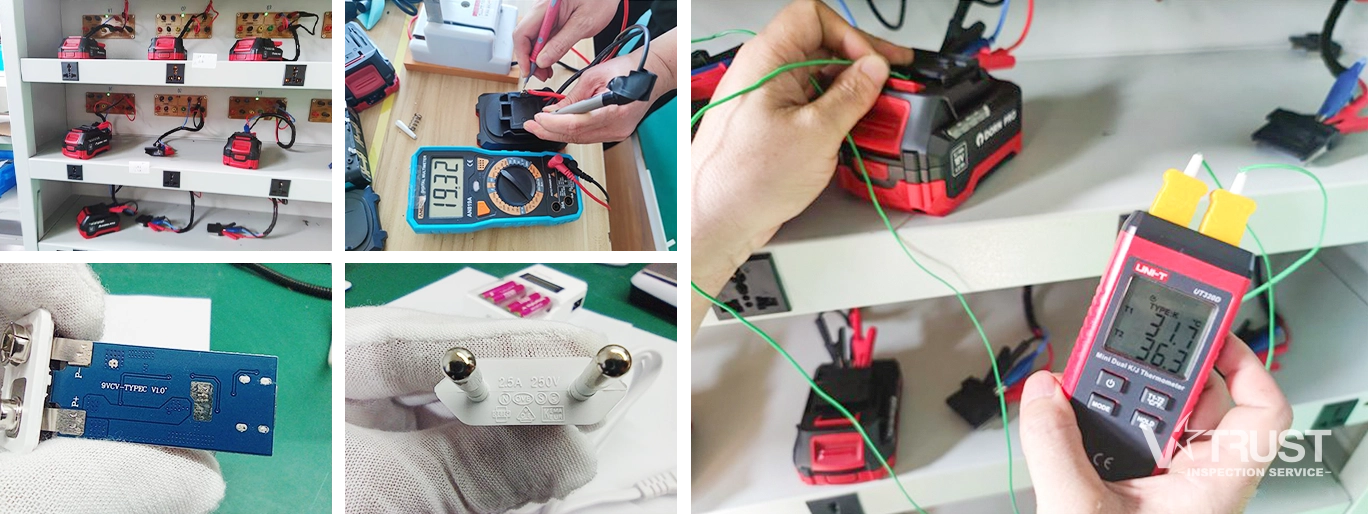

Product Inspection

We inspect Li-ion batteries onsite to verify quality, function, and workmanship against your exact specifications.

Supplier Audits

We audit battery manufacturers before your order to confirm their capability, process control, and quality system maturity.

Laboratory Testing

We test Li-ion batteries in our accredited labs for safety, regulatory compliance, and performance per target market requirements.

Voltage Check

Critical and Non-critical Alarms Check

6. How V-Trust Helps You Find the Right Li-ion Battery Supplier

We conduct supplier audits to verify production capabilities and compliance before order placement.

Factory Audit

Quick verification of supplier legitimacy, including:

- Factory existence and document verification (certificates, business licenses, etc.)

- Basic production capacity review

- Contact person verification

In-Depth Factory Audit

A comprehensive assessment of supplier reliability, covering:

- Production capacity & facility assessment

- Quality control system evaluation

7. How V-Trust Controls Li-ion Battery Quality

V-Trust delivers comprehensive Li-ion Battery inspection services, ensuring consistent product quality and regulatory compliance. Our quality control solutions cover all stages of Li-ion battery production, including Sample Checks, Production Monitoring, During Production Inspection, Pre-Shipment Inspection, and Container Loading Supervision, reducing the risk of product failures and costly recalls.

Sample Check

Our engineers evaluate battery samples for safety, capacity, cycle life, and certificates. We benchmark performance against your specs to identify optimal suppliers.

Production Monitoring

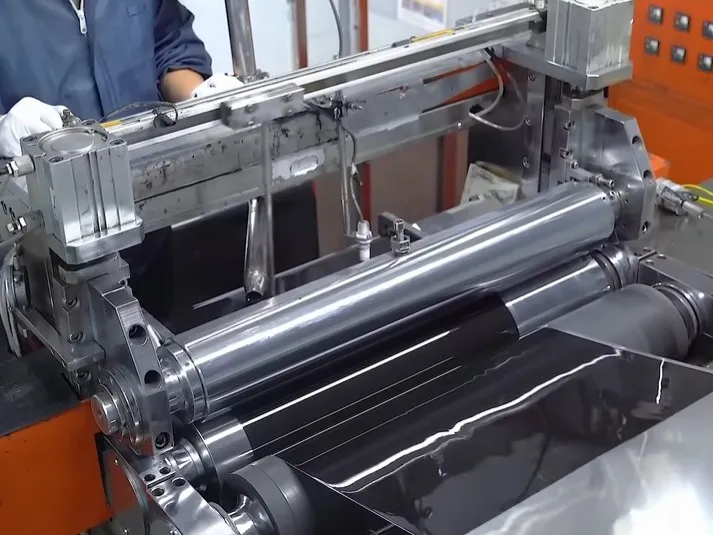

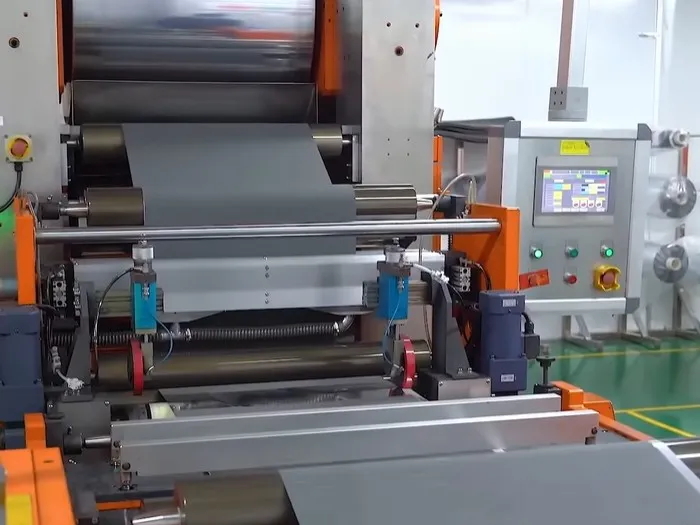

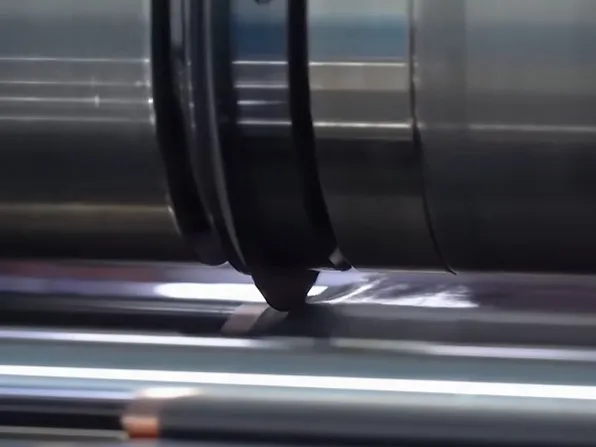

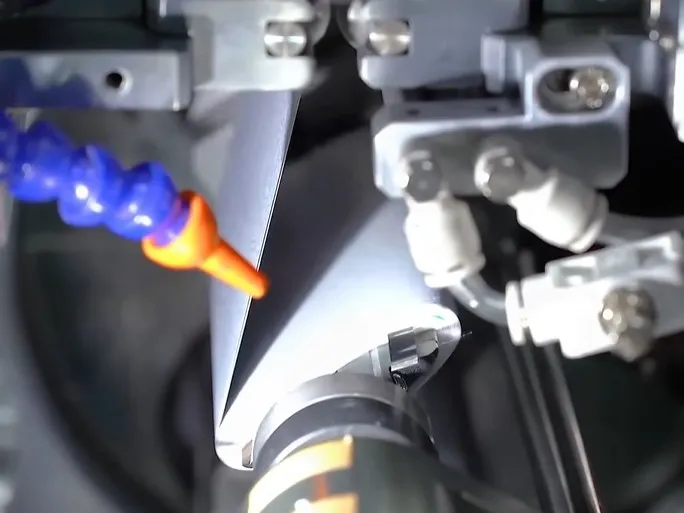

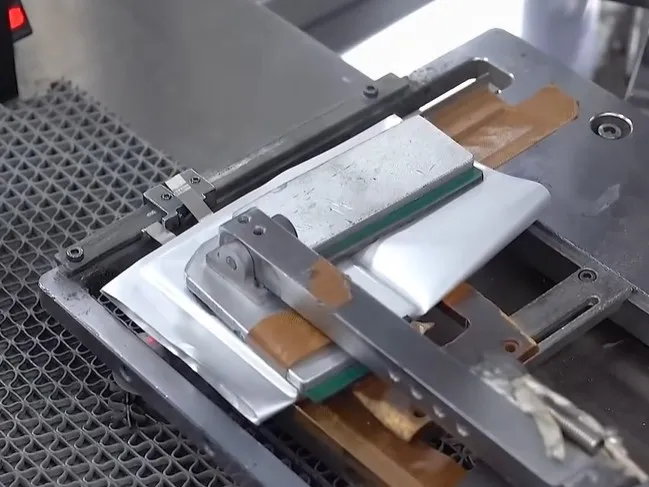

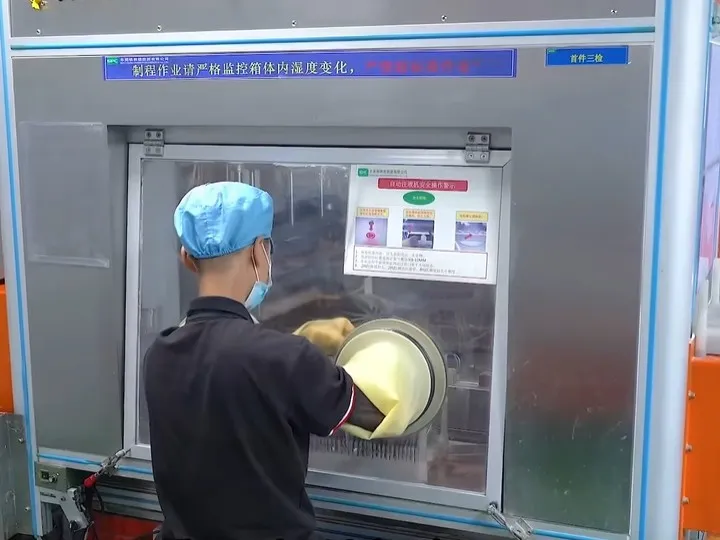

On-site oversight of electrode manufacturing, electrolyte filling, and sealing processes. We verify moisture control, spot weld integrity, and aging room protocols to prevent swelling/leakage defects at critical stages.

During Production Inspection

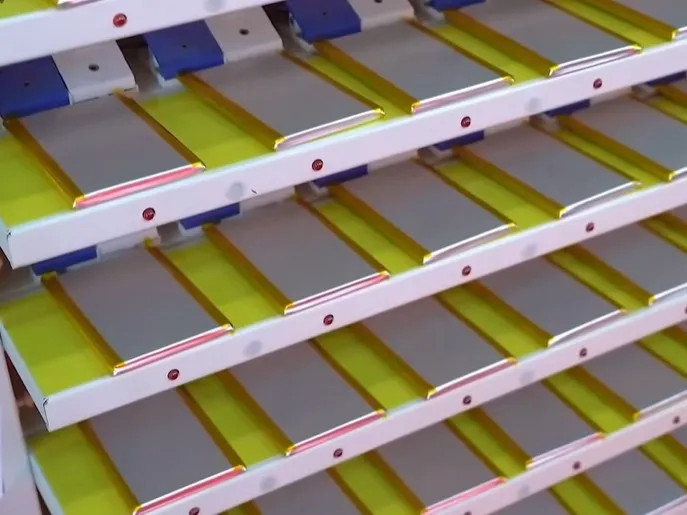

Once at least 10% of the Li-ion battery order is completed, our team performs a mid-production inspection to evaluate:

- Cell stacking alignment

- Tab welding strength

- Initial capacity/IR consistency

This early-stage inspection helps minimize rework and avoid late-stage surprises.

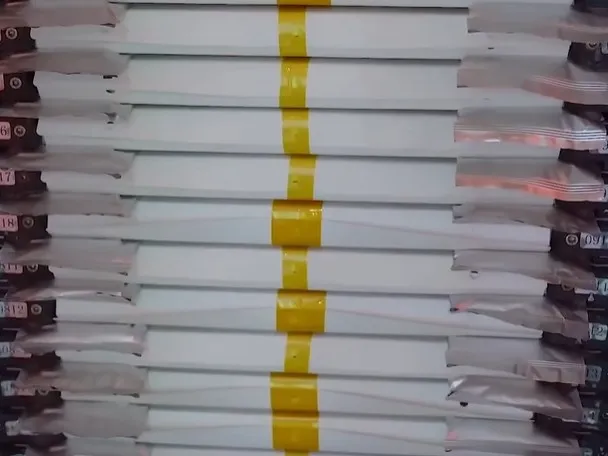

Pre-Shipment Inspection

Before shipping, we perform a thorough final inspection of your electric bikes to confirm:

- Safety: Hi-pot test, leakage current

- Performance: Capacity, cycle life

- Marking and labels: UN38.3 packaging, Class 9 labels

- 100% voltage/IR sorting

Container Loading Supervision

We verify pallet stacking, moisture barrier installation, and hazardous goods segregation. Container floor conditions and secure lashing are monitored to prevent damage or corrosion during transit.

8. The Most Related Sourcing Fairs in Asia

World Battery & Energy Storage Industry Expo (WBE)

China Import & Export Fair Complex, Guangzhou, ChinaAsia’s largest battery sourcing expo—lithium batteries, energy storage, EV packs, materials & equipment.

http://en.battery-expo.com/

The Battery Show Asia

AsiaWorld - Expo, Hong Kong, ChinaShowcasing battery materials, production equipment, energy storage solutions, and new energy transportation innovations.

https://www.thebatteryshow.asia/

China International Battery Fair (CIBF) (China)

Shenzhen World Exhibition & Convention Center, Shenzhen, ChinaCovering the entire battery industry chain, from raw materials and components to battery manufacturing equipment, testing devices, and various types of batteries.

https://www.cibf.org.cn/

Why Choose V-Trust for Li-ion Battery Products Quality Control?

Asia's leading product inspection company with full-time, professionally trained inspectors and comprehensive accreditation for inspection, audit, and lab testing services.

Li-ion Battery Products Quality Control: Frequently Asked Questions (FAQ)

Why do I need an inspection for batteries?

To prevent defects in functionality, safety, and compliance before shipment.

Do you test cycle life onsite?

We conduct accelerated cycle tests and verify BMS log data. Full lifespan tests require lab support.

How many days in advance should I book the inspection?

We recommend at least 3 days, but next-day inspections may be possible.

Do I need to send an approved sample?

Yes, approved samples help us verify specifications accurately.

How long does it take to get the report?

A draft is available the same day; the final report is issued within 24 hours.

What if I have questions after receiving the report?

Our team remains available for clarifications.

Request Your Inspection Today

Ready to ensure the quality of your products? Contact our team to discuss your specific requirements.